Robotics Impact Circuit Board Assembly Automation

As PCBs continue to evolve to meet the demands of modern electronics, automation and robotics are at the forefront. These technologies not only help manufacturers achieve greater precision, but also increase efficiency and improve quality. Those who wish to thrive in the fast-paced world of circuit board assembly should embrace these emerging technologies as a matter of urgency.

Robots are making major strides in industrial manufacturing and a variety of non-industrial sectors, from logistics to space exploration. Whether as space explorers or remotely operated surgeons, these “smart” machines perform repetitive tasks flawlessly and can handle complex operations that humans would find difficult. In fact, robots have already made significant gains in factory productivity and quality, making them an indispensable technology in the electronic industry.

The emergence of advanced sensor technology and software platforms that enable the intelligent manipulation of physical objects has enabled robots to become increasingly versatile. Today, they are used in a variety of applications including automotive manufacturing and consumer goods, as well as for specialized tasks such as medical treatment and assembly. Robots are now capable of interacting with and assisting humans at cognitive levels, allowing them to solve problems and adapt to changing environments.

How Advancements in Robotics Impact Circuit Board Assembly Automation

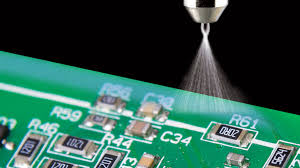

In the future, robots will be even more integral to the production process. As new robotics technology advances, they will be able to take on more sophisticated and flexible tasks, such as PCB assembly. In addition, they will be able to detect even the slightest defects during the assembly process.

This will allow manufacturers to reduce production costs and ensure that every single piece of a PCB is of the highest quality possible. As a result, companies that invest in these advanced systems will see their profits soar.

Historically, the fabrication of robots has been expensive and time-consuming. The computation, mobility, and manipulation capabilities of each robot are tightly coupled to its body, and adding new features requires extensive design work. Moreover, the body of a robot is hard to modify or expand. To achieve the flexibility and versatility required for a range of industrial tasks, engineers have created a class of ergonomic assist devices that allow humans to manipulate robots as though they were bionic extensions of their own limbs with increased reach and strength.

The advancements of robotics are transforming the way we live, work, and play. They will make it easier for us to control and integrate smarter, more connected electronic devices into our lives. These new devices will provide the foundation for a wide range of technological innovations, from the Internet of Things (IoT) to autonomous cars. Those contract manufacturers that adopt these cutting-edge technologies will be in the best position to compete with their competitors in the rapidly evolving world of electronics manufacturing.